IMDEA Energy is working on advanced methods to provide rapid information on the performance and durability of lithium-ion batteries

Lithium-ion batteries are known to be very versatile and attractive as an energy storage system in the emerging electric mobility sector. This is mainly due to their ability to store a lot of energy in a low weight and their excellent cycling properties compared to other battery types. Unlike lead or nickel batteries, whose charging and discharging involves substantial changes in the volume and structure of the species involved, lithium-ion batteries base their operation on the intercalation and de-intercalation of lithium ions in voids located in the electrode structure, a “softer” procedure that prevents degradation of the electrodes and ensures good cycling performance.

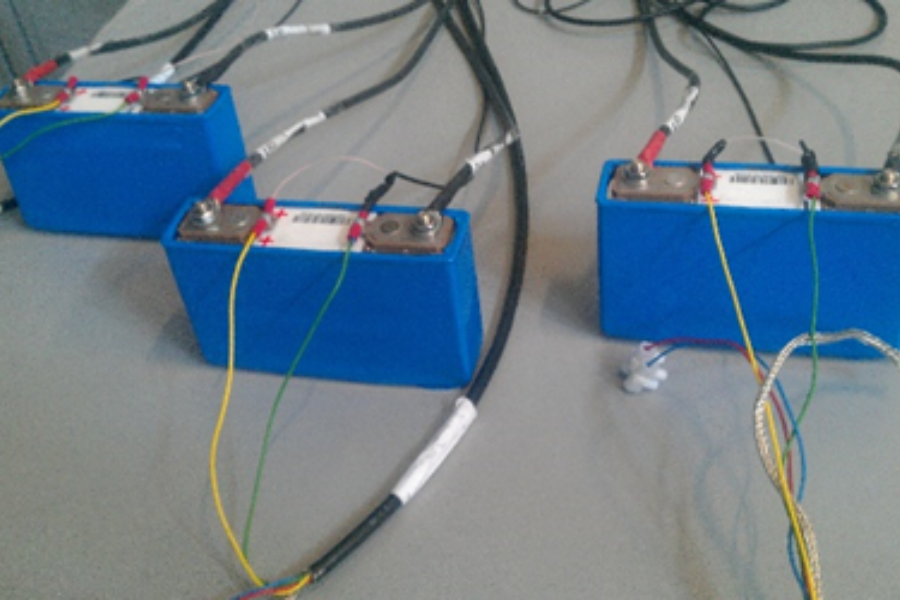

Health status measurements

This is beneficial for battery performance, but makes condition monitoring measurements more difficult and also lengthens the determination of lifetimes in emerging applications that are emerging recently. Rapid techniques that provide reliable information on battery condition within a few days or weeks are not currently available. This is because the performance they provide is so good that, if they are expected to last around 2000 cycles, they could be attributed a capacity retention of over 99.99% for each charge/discharge cycle, so that, with the techniques currently available and the accuracy of the equipment available, it is very difficult to measure these parameters in a few cycles.

Advanced battery testing methods

A research team at IMDEA Energía’s Electrochemical Processes Unit is developing LIB battery testing methodologies beyond the usual standards, focused on providing rapid information on the state of health and performance, and thus predicting durability under different operating conditions, which is especially relevant for a better understanding of future developments of this type of batteries.

In this sense, within the framework of the European Nanobat project, a new, inexpensive and easy-to-implement methodology has been proposed to analyse the quality of the Solid Electrolyte Interface (SEI) at the negative electrode of LIBs and thus predict the lifetime of the batteries.

The lifetime of lithium-ion batteries is limited by the degradation of the Solid Electrolyte Interphase (SEI), which is a passive layer that coats the negative electrode surface of most lithium-ion based batteries. After many charge and discharge cycles, it tends to decompose, consuming the lithium contained in the electrolyte and thus reducing the storage capacity.

The proposed technique consists of adding a molecule in the electrolyte that acts as a redox mediator causing an internal self-discharge process that is inversely proportional to the insulating characteristics of the SEI layer. Therefore, the presence of the redox mediator amplifies the impact of possible defects in the SEI film on the coulombic efficiency, so that they can be quickly detected even if conventional or low precision equipment is used.

Potential applicability

The findings based on the application of this coulometric method can be used for battery ageing studies and modelling in order to develop and optimise advanced battery testing methods.

The results of this research have recently been published in the journal ACS Applied Materials & Interfaces,

More information: https://doi.org/10.1021/acsami.2c11992