Cartera Tecnológica

Anaerobic conversion of Organic Wastes to Short Chain Fatty Acids and Biogass

Description

Anaerobic technology offers a compelling approach to waste management and resource recovery, minimizing environmental impact while fostering a circular economy where waste is transformed into valuable resources.

The key product of anaerobic digestion (AD) is biogas, a renewable energy source. Biogas can be used for heat and electricity generation, reducing dependence on fossil fuels and contributes to a more sustainable energy landscape. Beyond biogas, anaerobic fermentation (AF), a shortened AD process, can be used to produce short-chain fatty acids (SCFAs) such as propionic, butyric, caproic acids, among others. These SCFAs serve as sustainable alternatives to traditional petroleum-derived products for producing biofuels, bioplastics, and chemicals products.

Advantages and Innovations:

Anaerobic treatment offers significant advantages in using biowaste for the production of high-value organic acids and energy from biogas.

- In AF of agroindustrial waste, long hydraulic retention time promotes the SCFAs production, achieving a high total SCFAs concentration with significant chain elongation and caproic acid content.

- Canonical Correspondence Analysis can establish correlations between metabolite production and microbial community structure in the AF/AD of biowaste. This analysis reveals significant correlations between the abundance of a specific genera of microorganisms and high levels of specific acid or biogas.

- Biochemical methane potential (BMP) provides an early estimation of biogas production, identifying potential problems such as biodegradability, inhibition, and low inoculum activity. BMP test allows to suggest new strategies to improve the biodegradability of the biowaste.

- The addition of conductive materials (biochar, activated carbon, zero-valent iron, and iron nanoparticles) to anaerobic digesters enhances direct interspecies electron transfer, leading to increased methane production.

Market applications:

- Biowaste-derived SCFAs as sustainable intermediates for the chemical industry.

- BMP testing services to assess the biochemical methane potential of biowaste streams.

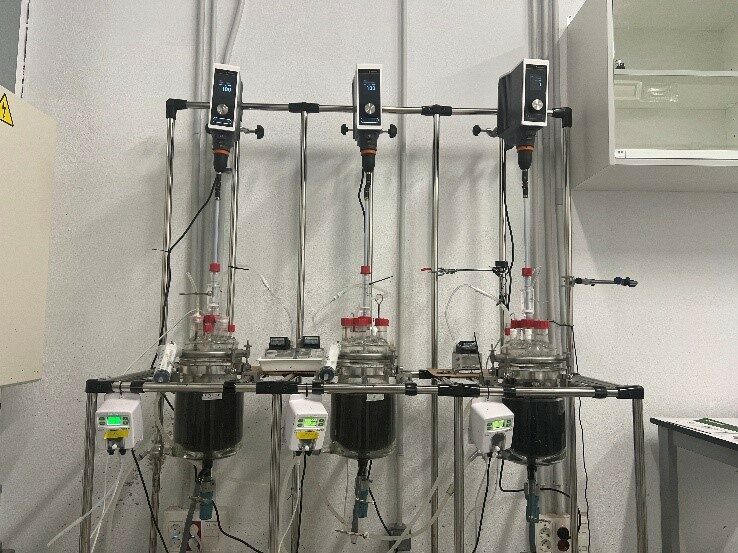

- Biogas production at different scales from 5-L to 50-L digesters establishing the feasibility of the process for implementation at industrial scale.

Contact

Félix Marín, felix.marin@imdea.org