Technological Offer

Microalgae cultivation in a versatile pilot plant

Description

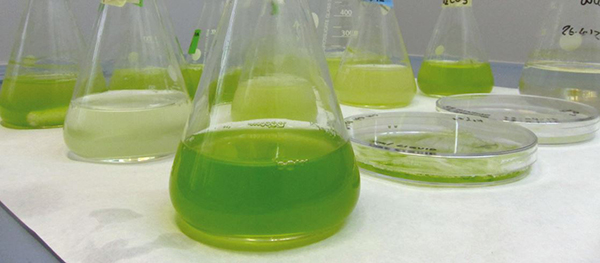

IMDEA Energy has a modern pilot plant to conduct photosynthetic microorganism cultivation in photobioreactors, This plant allows optimization and scaling up the microalgae/cyanobacteria/bacteria culture from laboratory to pilot plant scale. The process parameters automation and the on-line control through an advanced software provide high versatility and flexibility to the pilot plant operation. The scientific expertise related to bioprocess development and optimization, along with high-quality facilities, make this pilot plant especially attractive for research cooperation agreements while it is also offered the technical assistance to other partners that need to scale photosynthetic based technologies. Proof thereof is the number of national and international projects that have been developed using this facility and applying the know-how of the researchers.

This pilot plant includes 2 types of photobioreactos: 13 bubble columns (80 L per column) and 2 raceways (500 L per raceway) mixed by stainless steel paddle wheels. Each reactor is provided with rotameters to control air and CO2 flows. Likewise, nutrient supply, temperature, pH and illumination can be also regulated. The pilot plant also includes an area where inocula are prepared. This area includes reactors with smaller volumes (0.2-1 L) to cultivate photosynthetic microorganisms until the biomass is ready for scaling up. Additionally, the pilot plant is equipped with a fast harvesting system. Once the biomass is grown to the desired level, it is pumped to a reservoir of 0.5 m3 and subsequently concentrated by centrifugation in continuous mode. This separation process allows obtaining a clean effluent and a biomass with a reduced water content that can be further valorized.

The pilot plant offers high versatility to cultivate a wide range of photosynthetic microorganisms at different operational conditions, as well as non-photosynthetic microorganisms (aerobic or anoxic bacteria). The versatility of the pilot plant does not only rely on the different parameters that can be tuned but the options of operating the columns independently, triplicates or even connecting the columns to the raceways.

Advantages and Innovations

Compared with conventional wastewater processes for nitrogen removal (nitrification/denitrification), microalgae technology offers lower energy requirements and NOx emissions, as well as a continuous microalgae biomass production. In terms of the lower energy requirements, this is associated to the fact that oxygen is supplied to the biological system by photosynthetic means. Under this scenario, the aeration costs (that can represent up to 50 % of the operation in conventional wastewater treatments) is drastically diminished.

The flexible configuration and operation of the photobioreactors in terms of light irradiance, temperature, pH, air and CO2 supply, mixing, organic loading rate and feeding regime makes this pilot plant particularly efficient to: (i) optimize photosynthetic processes, (ii) select the most appropriated microalgae strain for subsequent commercial and research purposes and (iii) tune the most proper microalgae-bacteria consortium to maximize nutrient recovery from waste streams at industrial scale.

Market Applications

- Scaling up of biomass production under controlled conditions

- Cultivation of photosynthetic microorganisms at optimal conditions

- Comparison of microalgae and cyanobacteria production in various photobioreactor systems: raceways and bubbled columns

- Wastewater bioremediation via photosynthetic microorganisms or microalgae-bacteria consortia. Nutrient recovery as biomass.

Contact

Cristina González Fernández, Cristina.gonzalez@imdea.org