Optimised Battery Production and Nanoscale Testing: Launch of EU Research Project NanoBat

New nanotechnology solution to increase competitiveness of the e-mobility battery sector in Europe

The EU research project NanoBat aims to develop a novel nanotechnology toolbox for quality testing of Li-ion and beyond Lithium batteries with the potential to redefine battery production in Europe and worldwide. The targeted radio frequency (RF)-nanoscale techniques will be faster and more accurately calibrated than existing methods. The project will significantly reduce the costs of battery production thus greatly benefiting the evolving clean energy and e-mobility transition in Europe. The consortium comprises twelve academic and industrial partners and will receive EUR 5 million EU funding over the next three years.

Sustainable storage of electrical energy is among this century’s main challenges, and – as stated by the European Commission – battery production is one of the future key industries with an estimated market potential of EUR 250 billion by 2025. About one third of the production costs is related to the formation phase of the electrode SEI (solid electrolyte interphase) – an electrically insulated layer preventing ongoing electrolyte decomposition. In order to create a competitive manufacturing value chain for sustainable battery cells in Europe, reliable methods for measuring the quality and performance of batteries are of pivotal importance.

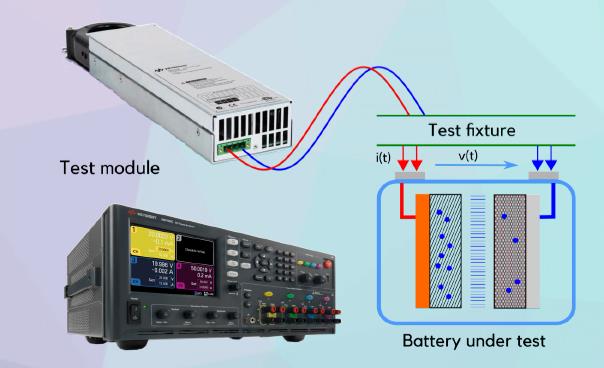

With the aim of surpassing currently available non-destructive quality testing techniques, the new European research project NanoBat has set out to develop an RF-nanotechnology toolbox to test Li-ion and beyond Lithium batteries. With a particular focus on the nanoscale structure of the SEI layer, this toolbox will contain novel high-frequency GHz methods to test and quantify the electrical processes at the SEI which are responsible for battery performance and safety, but difficult to characterise and optimise.

“Covering the EU demand alone requires at least 20 large-scale battery production facilities”, says Project Coordinator Dr Ferry Kienberger from Austria-based industry partner Keysight Technologies. “We are confident that the NanoBat technologies could effectively support European manufacturers and SMEs to exploit this enormous market potential and keep up with global competition.”

Besides fostering the EU’s industrial competitiveness and innovation capacity, the NanoBat developments will have a positive impact on the circular economy and the environmental footprint of battery production, as more precise testing methods will result in a decrease of energy and raw material use and waste.

In order to achieve their ambitious project goals, the consortium will follow four methodological steps:

- Development of four new scientific multi-scale RF-instrumentations for off-line, in-line and real-time measurements

- Establishment of modelling and predictive analytics tools for the SEI layer including physics-based GHz models

- Studies of advanced cell materials and first demonstrator tests in the smaller pilot lines

- Scale-up considering specifications and targets from the industry

In the course of the 3-year project, the new methods will be tested first in pilot-lines focusing on batteries for e-cars and special applications in aerospace. After project conclusion, the green production methods can be scaled up through the involvement of global players in the automotive industry and spread to additional markets, such as speciality batteries for satellites, green buildings, GHz-materials or modelling software.

The NanoBat consortium comprises twelve academic and industry partners with complementary expertise who will be supported by an Advisory Board of end users, science communities, EU policy makers and standardisation authorities. Additionally, the project will foster technological cooperation by establishing a stakeholder group including key industry players within and beyond the EU.

In the framework of the NanoBat project, the Electrochemical Processes Unit of IMDEA Energy will develop an accelerated battery ageing method to assess the quality of battery cells and predict their cycle life in a 24h – 48 h test.

Download the project flyer here (link to the project flyer)

Project Key Facts

- Austrian Institute of Technology GmbH, Austria

- Centro Ricerche Fiat, Italy

- EURICE – European Research and Project Office GmbH, Germany

- Federal Institute of Metrology METAS, Switzerland

- IMDEA Energy Institute, Spain

- Johannes Kepler University Linz, Austria

- Keysight Technologies GmbH, Austria

- Kreisel Electric GmbH & Co KG, Austria

- Pleione Energy S. A., Greece

- QWED, Poland

- Ruhr-Universität Bochum, Germany

- Technische Universität Braunschweig, Germany

Contact

The NanoBat project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 861962. The information in this document is provided "as is", and no guarantee or warranty is given that the information is fit for any particular purpose. The user uses the information at its sole risk and liability.

Tags: Batteries Evaluation, Nanobat, Battery, European Project