Turning municipal biowaste into fuels through catalytic pyrolysis

Thanks to science and the development of technology, most societies today have achieved standards of comfort and health that might well have seemed like science fiction to our not-too-distant ancestors. But this standard of living, sustained by a system of linear economics, and based on making a quick profit through the production of “throwaway” goods, is no longer sustainable. The impact that this model has had on the environment and has put the availability of certain resources at critical risk has highlighted the need to take action to mitigate or, as far as possible, reverse the situation.

The circular economy proposes a new production model, where the maxim is sustainability to ensure the preservation of the environment and resources for future generations. To this end, the improvement or development of new technologies is sought to increase efficiency, as well as the use of planet-friendly energies.

One of the most innovative actions is to convert waste into raw materials that can be reintroduced into production cycles for as long as possible and thus minimise its final management as waste. In this context, IMDEA Energía’s Thermochemical Processes Unit is working on the development of catalysts and processes adapted to the valorisation of solid organic waste, converting it into liquid fuels or chemical products of commercial interest.

In particular, it is committed to catalytic pyrolysis technology, where waste is decomposed by the effect of temperature, in the absence of oxygen, and with the assistance of a catalyst. Pyrolysis usually results in three types of products: a gas, consisting mainly of CO2, CO and volatile hydrocarbons; a carbonaceous solid with different potential uses; and an organic liquid, a source of combustible hydrocarbons and/or commercial chemical compounds. The proportion and properties of the pyrolysis products depend on various factors that have to be explored and optimised, notably the type of waste, the operating conditions and the type of catalyst used.

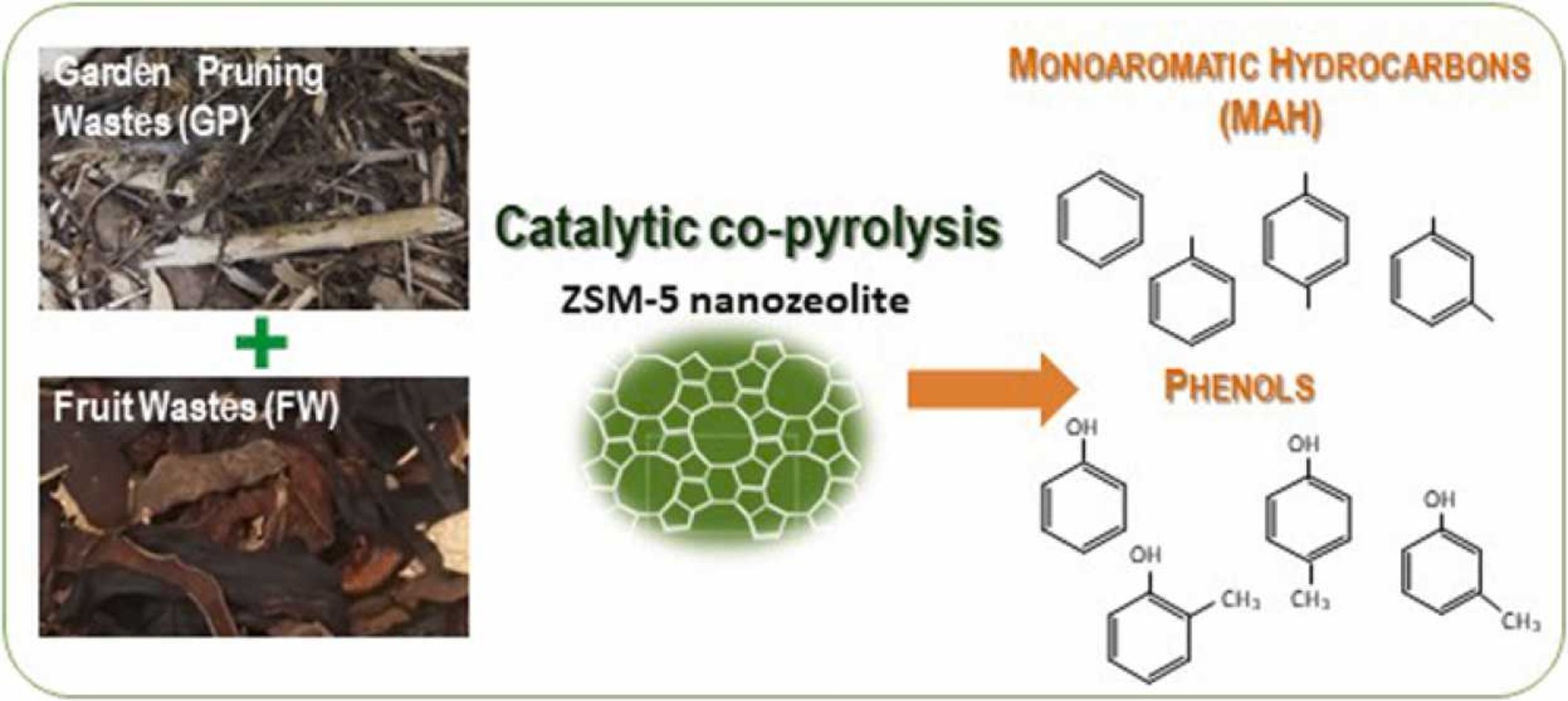

Among the wastes evaluated by the Thermochemical Processes Unit are food waste and garden prunings, which are common in urban bio-waste. These have been selected because the management of urban bio-waste is one of today’s major environmental concerns. For example, in the European Union they represent the largest single fraction among municipal solid waste (34% on average of the total waste stream) with a generation rate of approximately 88 tonnes each year. By co-processing both types of waste together, and using a zeolitic catalyst under optimised reaction conditions, the research team has been able to significantly improve the yield to products of high commercial interest, such as monoaromatic compounds (toluene, xylene and alkylbenzenes).

More information: https://doi.org/10.1016/j.jece.2022.107738