SUN-to-LIQUID project publishes successful thermochemical kerosene production using solar energy, water and CO2 in an integrated solar experimental facility in the scientific journal Joule

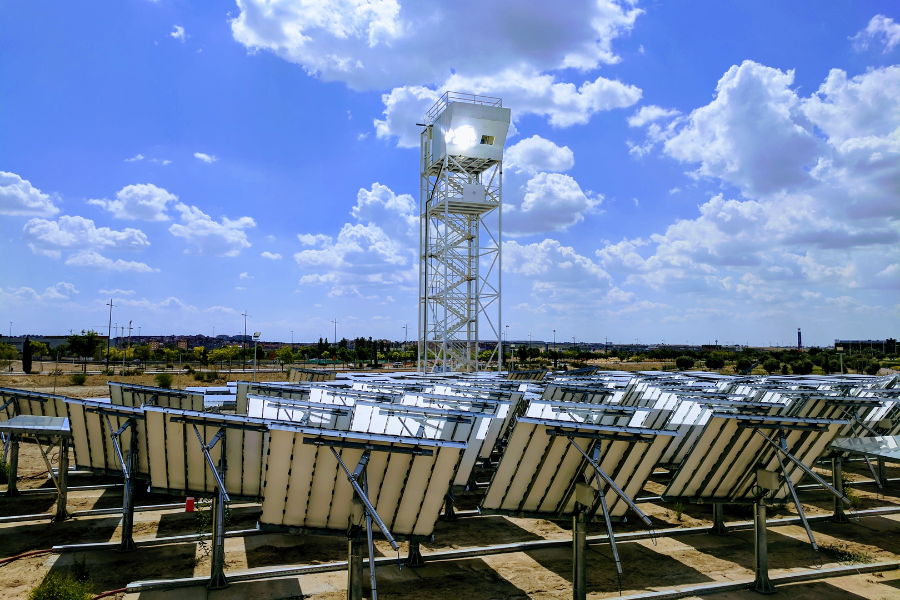

Developing solar technologies for producing carbon-neutral aviation fuels has become a global energy challenge, but their readiness level has largely been limited to laboratory-scale studies. Here we report on the experimental demonstration of a fully-integrated thermochemical production chain from H2O and CO2 to kerosene using concentrated solar energy in a solar tower configuration. The co-splitting of H2O and CO2 was performed via a ceria-based thermochemical redox cycle to produce a tailored mixture of H2 and CO (syngas) with full selectivity, which was further processed to kerosene. The 50 kW solar reactor consisted of a cavity-receiver containing a reticulated porous structure directly exposed to a mean solar flux concentration of 2,500 suns. A solar-to-syngas energy conversion efficiency of 4.1% was achieved without applying heat recovery. This solar tower fuel plant was operated with a setup relevant to industrial implementation, setting a technological milestone towards the production of sustainable aviation fuels.

Developing solar technologies for producing carbon-neutral aviation fuels has become a global energy challenge, but their readiness level has largely been limited to laboratory-scale studies. Here we report on the experimental demonstration of a fully-integrated thermochemical production chain from H2O and CO2 to kerosene using concentrated solar energy in a solar tower configuration. The co-splitting of H2O and CO2 was performed via a ceria-based thermochemical redox cycle to produce a tailored mixture of H2 and CO (syngas) with full selectivity, which was further processed to kerosene. The 50 kW solar reactor consisted of a cavity-receiver containing a reticulated porous structure directly exposed to a mean solar flux concentration of 2,500 suns. A solar-to-syngas energy conversion efficiency of 4.1% was achieved without applying heat recovery. This solar tower fuel plant was operated with a setup relevant to industrial implementation, setting a technological milestone towards the production of sustainable aviation fuels.

Context, Scale, and Significance:

The aviation sector, which strongly relies on fossil-derived kerosene, is responsible for vast amounts of anthropogenic greenhouse gas emissions. To avoid these emissions, solar energy can be leveraged to efficiently produce sustainable drop-in fuels (e.g. kerosene). Solar-made kerosene can replace fossil-derived kerosene and further make use of the existing global jet fuel infrastructures for its storage, distribution, and end-use in jet engines, which are particularly critical for the long-haul aviation sector.

For the first time, the thermochemical production of kerosene using solar energy, water, and CO2 is demonstrated in a fully-integrated solar tower fuel plant. This work, realized within the framework of the EU Horizon 2020 project SUN-to-LIQUID, advances the technological readiness level of solar fuels production by demonstrating the technical feasibility of the entire sun-to-liquid fuel process chain. We have evaluated the performance of the solar reactor − the cornerstone technology − based on five primary metrics (namely: reaction selectivity, syngas quality, fuel purity, energy efficiency, and material stability) and experimentally validate its stable operation and full integration in the solar tower fuel plant. This pioneer technological demonstration, performed at a pilot scale relevant to industrial implementation, represents a critical milestone on the path towards the production of sustainable aviation fuels.

The aviation sector, which strongly relies on fossil-derived kerosene, is responsible for vast amounts of anthropogenic greenhouse gas emissions. To avoid these emissions, solar energy can be leveraged to efficiently produce sustainable drop-in fuels (e.g. kerosene). Solar-made kerosene can replace fossil-derived kerosene and further make use of the existing global jet fuel infrastructures for its storage, distribution, and end-use in jet engines, which are particularly critical for the long-haul aviation sector.

For the first time, the thermochemical production of kerosene using solar energy, water, and CO2 is demonstrated in a fully-integrated solar tower fuel plant. This work, realized within the framework of the EU Horizon 2020 project SUN-to-LIQUID, advances the technological readiness level of solar fuels production by demonstrating the technical feasibility of the entire sun-to-liquid fuel process chain. We have evaluated the performance of the solar reactor − the cornerstone technology − based on five primary metrics (namely: reaction selectivity, syngas quality, fuel purity, energy efficiency, and material stability) and experimentally validate its stable operation and full integration in the solar tower fuel plant. This pioneer technological demonstration, performed at a pilot scale relevant to industrial implementation, represents a critical milestone on the path towards the production of sustainable aviation fuels.

Alongside IMDEA Energy, the SUN-to-LIQUID consortium includes other research centres and companies involved in the thermochemical production of solar fuels, such as Bauhaus Luftfahrt e.V., ETH Zurich, DLR, Abengoa, ARTTIC and HyGear.

More information: https://doi.org/10.1016/j.joule.2022.06.012