IMDEA Energy works in sustainable production of bioplastics from plant residues urban waste

Over the past decades, petroleum-based plastics have contributed to global economic development and brought great benefits to society. Due to their low cost, good durability and processability, millions of tons of plastics are used annually in numerous applications. In 2018, global plastic production was 359 million tons and this amount is expected to increase in the coming years mainly due to the development of new industrial applications and the modernization of emerging economies.

Of all the plastic waste generated worldwide only 18 percent is recycled and 58 percent is either dumped directly into landfills or accumulates in the natural environment over a long period of time. This has resulted in microplastic pollution reaching an alarming level in the air, water and different forms of marine animals.

This situation, together with resource depletion and greenhouse gas emissions, makes a shift towards more sustainable plastic production models mandatory to achieve social welfare.

Bioplastics, produced from organic waste through biological processes, can play a key role in achieving a more sustainable society. Among the different types of bioplastics, polylactic acid (PLA) has a wide versatility and can be used in a multitude of industrial sectors, such as cosmetics, medicine and food. However, the growth of the bioplastics market is subject to the availability and cost of raw materials.

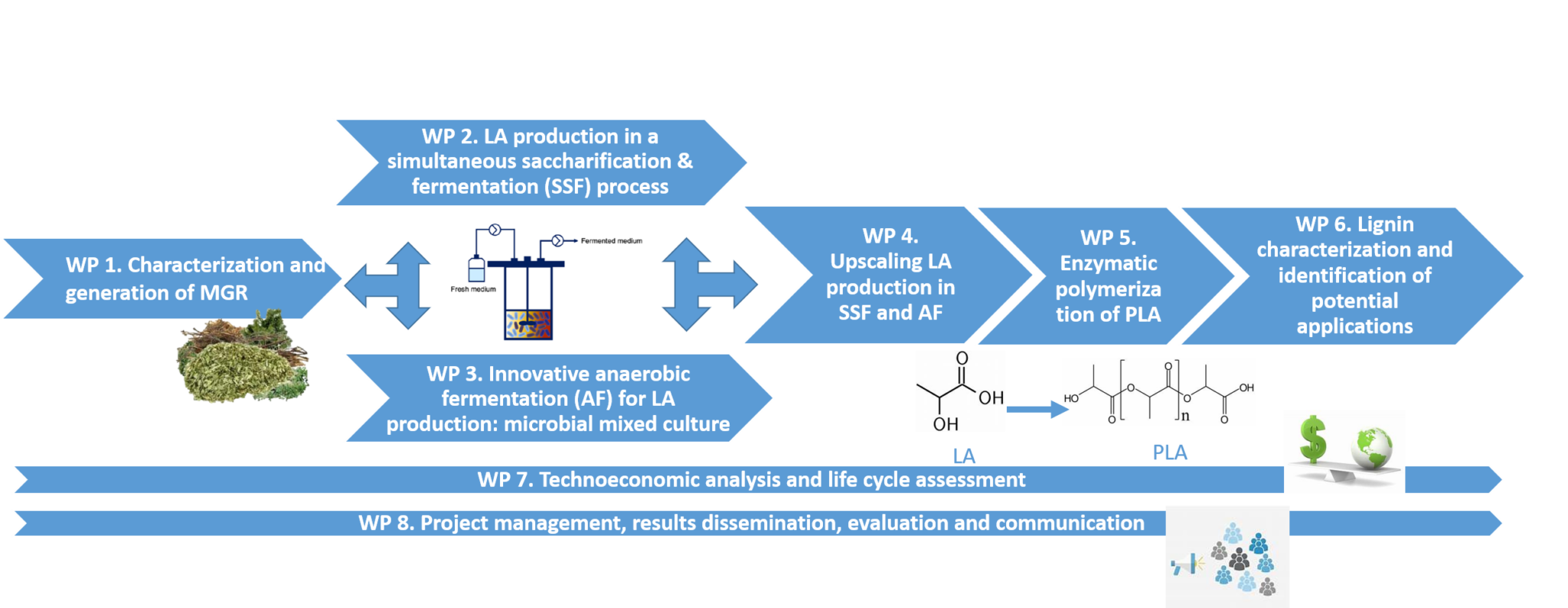

The expansion of urban plant areas leads to the generation of large quantities of lignocellulosic waste, which, at a low cost, could be used to produce platform molecules such as lactic acid, from which PLA is generated.

In this context, the RESOPLA project, led by the Biotechnological Processes Unit of IMDEA Energía and carried out in coordination with the Biofuels Unit of CIEMAT, addresses the valorization of urban vegetable waste for the production of PLA. To this end, different innovative biotechnological pathways and routes are being evaluated to simplify the process towards the efficient and economic production of bioplastics from urban vegetable waste.

Compared to conventional plastics, the production of bioplastics is still small. Therefore, the potential for growth, innovation and development in the field of production of economically competitive bio-based bioplastics is still enormous.