Technological Offer

Photocatalytic tests

Description

Three kinds of photocatalytic tests of energy interest are offered to measure the photocatalytic activity of powdered materials susceptible of acting as photocatalysts for CO2 conversion and/or hydrogen production via water splitting or photoreforming.

Tests to measure the photocatalytic activity of powdered materials for CO2 conversion and hydrogen evolution are offered. Three kinds of tests are possible:

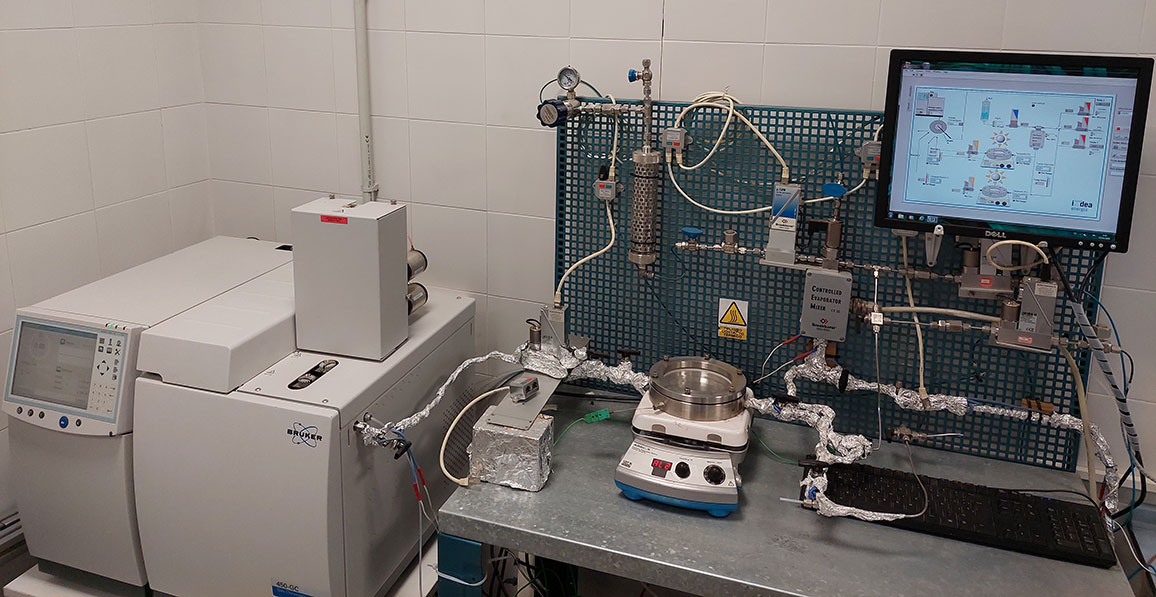

Gas-phase CO2 conversion experiments are conducted in continuous- flow mode in a stainless-steel reactor with an effective volume of 280 mL and provided with a borosilicate window for irradiation. An aqueous suspension of 100 mg of the powdered catalyst is deposited on a glass microfiber filter, dried at 100 °C under vacuum and fitted inside the reactor. UV and visible lights can be used used as irradiation source. Pure CO2 and water are fed into the reaction system using a Controlled Evaporation and Mixing (CEM) unit. The reaction conditions are 2 bar and 50 °C. The products of the reaction are determined in-line by a gas chromatograph equipped with three columns (BR-Q Plot, BR-Molesieve5A and CP-Sil5B), two thermal conductivity detector (TCD), a flame ionization detector (FID) and a methanizer. Virtually any CO2 conversion product can be detected and quantified.

Liquid-phase photocatalytic hydrogen production experiments are carried out in a Pyrex glass reactor incorporating a water-cooled immersion low-pressure mercury lamp and connected to an argon line. In-line analysis of the outlet gas was performed with a dual- channel micro-GC 490 from Agilent Technologies, equipped with MS5A PLOT and PoraPLOT U columns and TCD detectors. In a typical experiment, 20 mg of the powdered catalyst are suspended in an queous solution of an electron dodnor (typically methanol) under vigorous magnetic stirring. Argon is flowed through this suspension to remove air and carry the product gases. After air is totally removed, irradiation is started.

Gas-phase H2 production experiments are conducted in continuous- flow mode. Ca. 10 mg of the powdered catalysts are deposited on a glass microfiber filter that is then placed in a stainless steel reactor of 10.8 cm3 volume, provided with a borosilicate glass window for external irradiation. The reactor was fed by an Ar flow that is passed through a bubbler containing an aqueous solution of a volatile electron donor (typically methanol) kept at 60°C. The reactor is maintained at the same temperature throughout the experiment. Hydrogen evolution is monitored by in-line mass spectrometry.

Advantages and Innovations

The offered tests allow to explore the photocatalytic activity of powdered materials for the mentioned reactions with relatively low amounts. The different possible conditions mean a considreable experimental versatility.

Market Applications

- Photocatalysis

- CCSU technologies

- Hydrogen

Contact

Félix Marín, felix.marin@imdea.org