Students from the Universidad Rey Juan Carlos explore IMDEA Energy on several educational visits

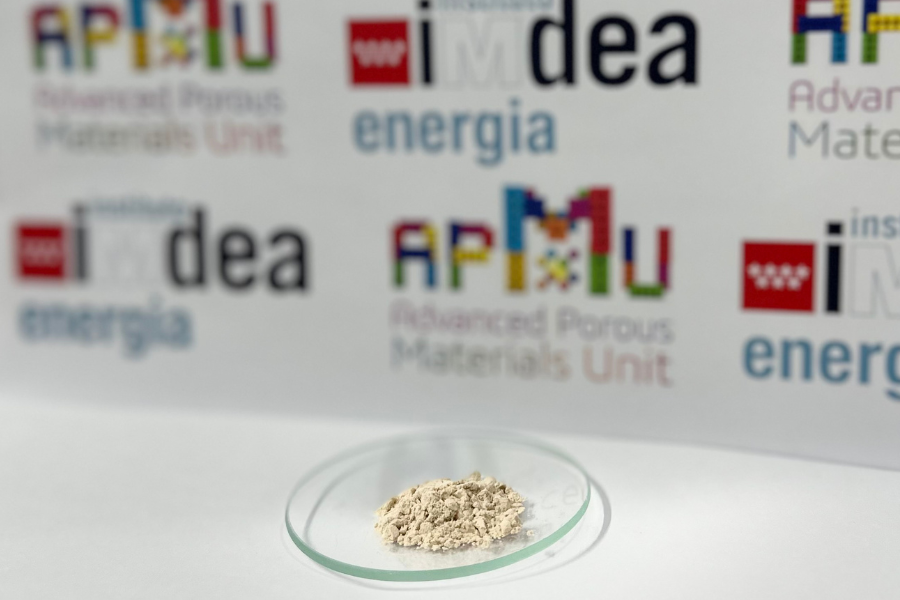

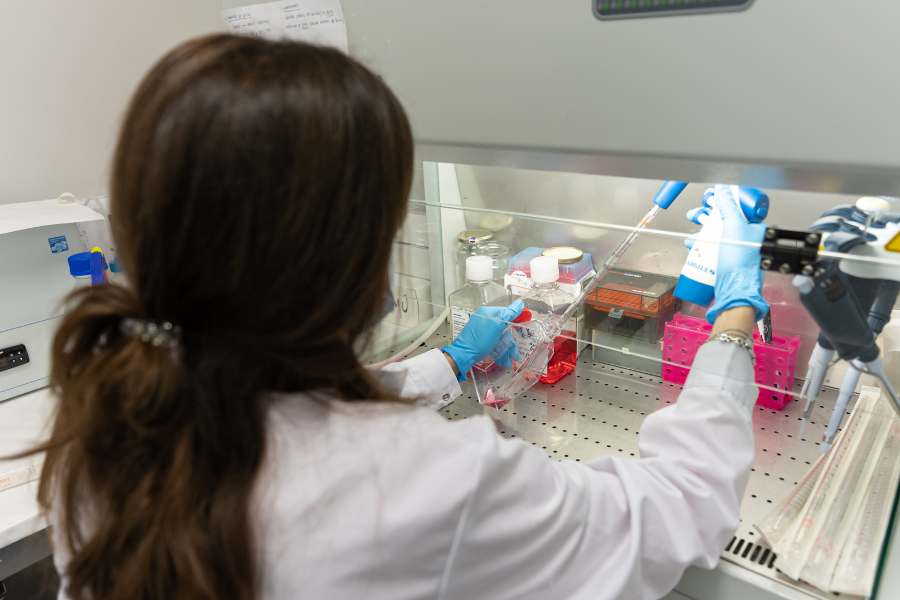

Nearly one hundred students from the Fuel Technology course of the Energy Engineering Degree at the Universidad Rey Juan Carlos have visited IMDEA Energy’s scientific facilities to learn more about the research techniques used and the projects on which the units that make up the centre are working.

During the activities, organised on 15 April and 6 May, the students explored the laboratories of the Thermochemical and High-Temperature processes units, as well as the pyrolysis pilot plant, the solar simulator and the heliostat solar field, through the explanations of the research staff of these areas.

In addition to solving theoretical and practical questions related to their area of study, the students have learned about issues related to a research career, such as the development of a thesis or an internship at IMDEA Energy